Khan Shatyr Entertainment Centre

Contents |

[edit] Introduction

The city of Astana, Kasakhstan’s newly created capital, brings a unique set of environmental challenges. Its remote steppe location to the north of the country experiences temperatures below freezing for half the year with extremes ranging from - 40ºC to +40ºC. The Kahn Shatyr (Big Tent) provides 100,000m2 of floor space where the people of Astana can meet, shop and relax year round in comfort despite the extreme environment. It was opened on the birthday of President Nazarbayev in July 2010 as a gift to the people, the 150m high mast acting as a beacon to the surrounding countryside.

[edit] Initial concept

Challenged with creating a giant, free-spanning enclosure with the minimum of support, the engineers (Buro Happold) felt that a single-masted cable net in a conical form was the natural choice due to its simplicity and efficiency of material. With a single compression mast to lift the net and create a large volume underneath, the roof skin is in tension and can use cables rather than beams to carry all loads. It also creates a very strong “iconic” form on the skyline – a critical consideration for such an important building in the capital city.

[edit] Structural design

The 19,000m2 transparent roof of the Entertainment Centre comprises ETFE (Ethylenetetrafluoroethylene) cushions supported on a cable net structure. The roof cables are collected 90m above ground on a ring at the top of the steel tripod and span to the sloped concrete perimeter which forms the base of the building. Four intersecting arcs define the 140m long, 120m wide plan of the roof.

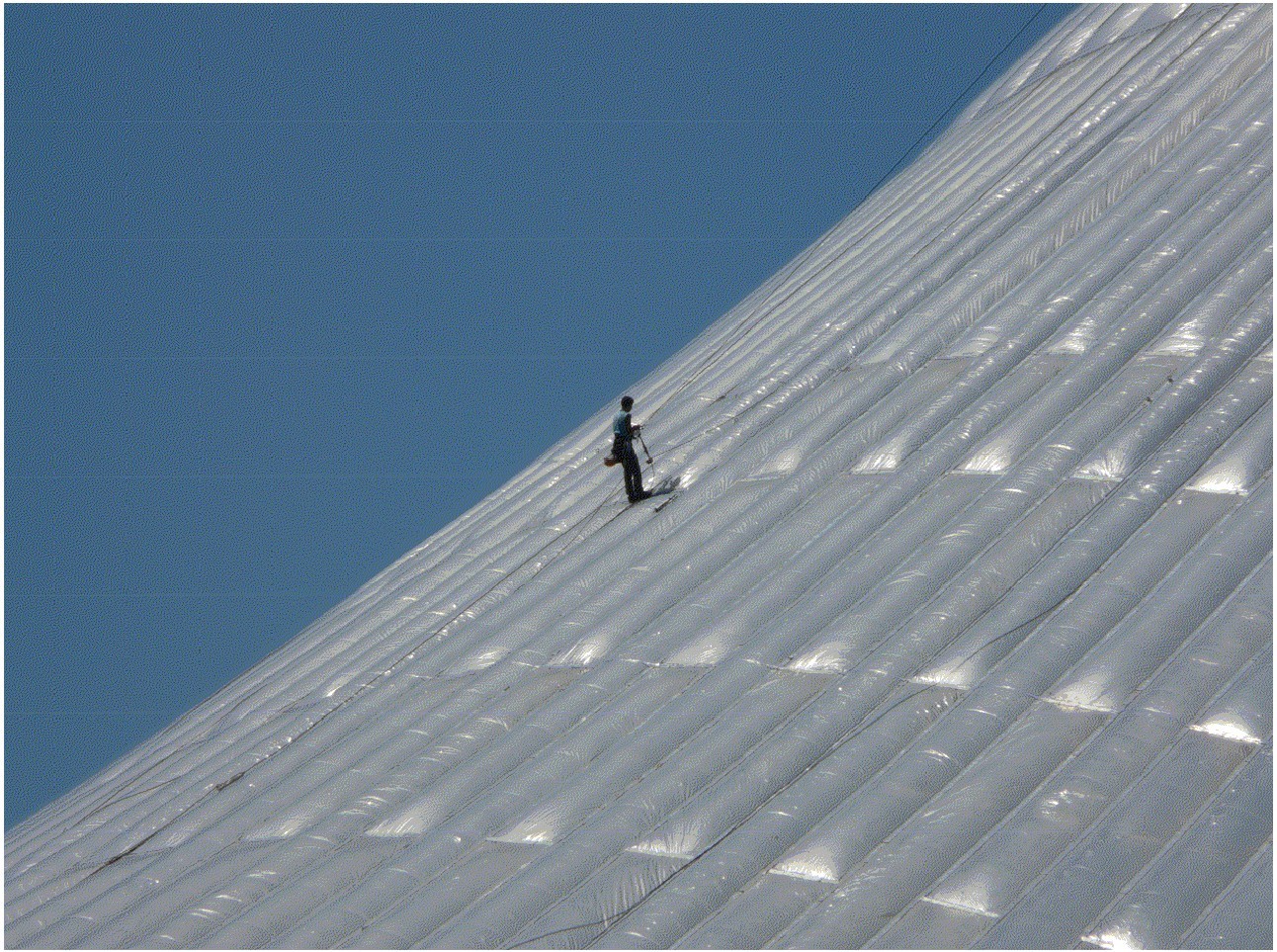

The skin of ETFE cushions is very lightweight and insulates while still providing natural daylight. The cushions are flexible to accept the large deflections of the cable net, however their frames are much more rigid, and so Vector-Foiltec developed a staggered arrangement of cushions. This allows the hoop frame of one panel to squeeze in on the mid point of the adjacent panel and benifit from the inherent flexibility of the cushion.

The shape of the cable net is based on a classic cone which has been pulled over to one side to better relate to the internal layout. This gives the Entertainment Centre its distinctive sloping architectural form. Radial cables span from the top ring of the steel compression mast to the outer concrete perimeter and are prestressed against hoop cables to form an anticlastic surface. 192 pairs of 38mm diameter radial cables vary in length from 125m at the front of the tent to 70m at the back. The hoop cables are arranged perpendicular to the ridge line of the radials. A relatively high prestress of about 80% of the peak cable forces is utilised in the tent to control deflections to around 800mm over the longest cable span.

The tripod provides the single point of support to the centre of the cable net and is an important element for the architecture of the building. Traditionally the central support of a conic tent is a single mast, pinned at both the top and the bottom and stabilised by the tent that it supports. This only ever places axial force in the mast which moves with the tent under asymmetric loads and reduces the peak tensions within the cable net. However, it was felt impractical to temporarily support a fully articulated 150m high single mast during construction so this principle was adapted for the Entertainment Centre. The tripod structure which is used provides a robust constructible base while the articulated top ring that it supports provides some movement to relieve the forces in the cable net. The movable part of the mast is then a much smaller element that was easier to temporarily brace during construction.

Each tripod leg is formed from a three chord truss with 1000mm diameter circular hollow main sections, the back leg resists 140MN while each front leg resists 50MN. The legs meet at a hub which supports 12 pin ended struts reaching to the cable net top ring. The pin connections for the 800mm diameter struts allow the articulation of the top ring. The hub is located so that its centre line corresponds with the resultant axial force from the cable net under prestress loads.

[edit] Construction

Despite the harsh climate, construction on the Khan Shatyr took place all year round undertaken under the direction of Sembol using a number of specialist contractors to enable the opening for President Nazarbayev’s birthday in 2010.

The greatest challenge to overcome in the construction process was the erection of the tripod. Buro Happold developed the design in discussion with Samko who were the specialist steelwork sub-contractor. The general arrangement of the tripod was configured to allow a dramatic single lift process where the whole 1,700 ton tripod was pivoted around pins at the bases of the two front legs. Strand jacks, attached to the top of a temporary tower in front of the tripod, pulled on lifting cables attached to a frame on the tripod hub. As the front legs pivoted up, the top of the back leg lifted on a temporary pin connection under the hub whilst its base slid in on a bogey running on a rail track. Temporary bracing to the cable ring remained in place until the cables had been installed and correctly prestressed.

Although the tripod provided the most dramatic sequence in the construction of the Khan Shatyr, the installation of the cable net was also challenging. The radial cables were lifted individually into a slack condition with cable clamps attached ready to accept the hoop cables which were placed over the top of the radials. Once all the cables were in place tension was pulled into them using a jacking detail at the base of the radial cables to bring the net into shape and allow the installation of the cushions to proceed.

The ETFE cushions were slid into their extrusions from the base and pulled through to the top. The length of the cushions were maximised to reduce their number and make the installation as fast as possible, but during the winter months the cold temperatures made the ETFE much harder to work and tension.

[edit] Conclusion

The design and construction of the Khan Shatyr Entertainment Centre was only achieved by harnessing the expertise of an international team of designers and contractors working closely together. It has successfully overcome significant challenges to provide a unique, large, open space for the people of Astana to use all year round in comfort despite the climatic extremes that the city experiences.

[edit] Acknowledgements

- Main Contractor/Developer - Sembol

- Architect - Foster + Partners

- Engineer - Buro Happold

- Structural Design and Build Contractors:

- Steelwork - SAMKO Group (Engineer - Arce Engineering)

- Cable Net - Montage-Service (Engineer - Teschner Ingenieure)

- ETFE - Vector-Foiltec

This article was created by --Buro Happold.

Featured articles and news

UKCW London to tackle sector’s most pressing issues

AI and skills development, ecology and the environment, policy and planning and more.

Managing building safety risks

Across an existing residential portfolio; a client's perspective.

ECA support for Gate Safe’s Safe School Gates Campaign.

Core construction skills explained

Preparing for a career in construction.

Retrofitting for resilience with the Leicester Resilience Hub

Community-serving facilities, enhanced as support and essential services for climate-related disruptions.

Some of the articles relating to water, here to browse. Any missing?

Recognisable Gothic characters, designed to dramatically spout water away from buildings.

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

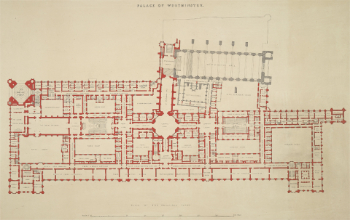

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.